Cartridge type dust collectors

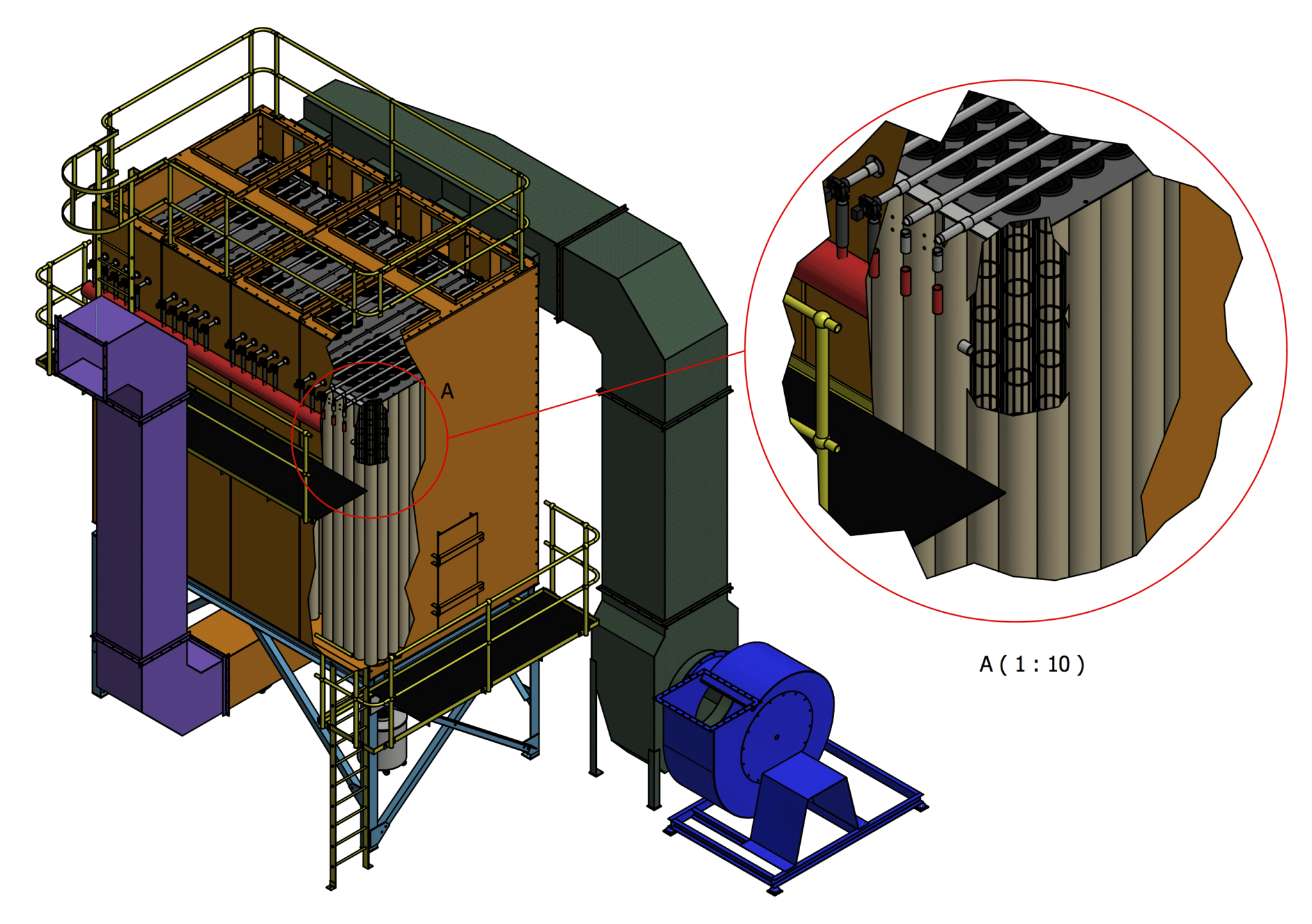

Cartidge type dust collectors operate in a similar manner to bag type dust collectors. There are numerous cartridges inside the dust collector that provide a large surface area for filtration.

The filter bags are periodically cleaned by fresh air pulses from PLC controlled pulsating valves. The pulsating air that is released creates a shock pulse on the bag which causes the dust to fall of the filter cartridges.

The cartridges typically provide excellent air cleanliness of over 99%.

Cartridge type dust collectors are more compact than cylindrical cage-type duct collectors as they have a greater surface area. They can also be design to be changed from the front of the dust collector instead of the top reducing ceiling height requirements.

Cyclones

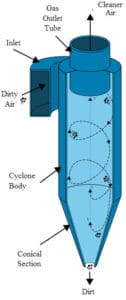

A cyclone can be used by itself in order to reduce the amount of dust expelled in a system or in conjunction with a filter type dust collector to collect larger particles before the dust collector.

In a cyclone the air enters at the top and is forced into a circular downward “cyclonic” pattern. The heavy particles drop out of the air stream as their velocity decreases. Cleaner air leaves the cyclone from the top.

Cyclones are used in many applications but are common in the woodworking industry and in industries that generate larger “dust” particles such as recycling.

Contact us for your dust requirements - we can design a custom solution for your needs. See some of our recent installations below.